What’S Included in a truck scale installation?

So you picked out your new truck scale and are ready to start weighing trucks. However, before any weighing can start, your new truck scale needs to be installed. Installation of a truck scale includes a number of different components that your local scale dealer will complete. The main areas of the installation include setting the scale, anchoring the scale, running all cabling, wiring the scale, setting up peripheral devices, calibrating the scale, and placing the scale into service. Below we will review each area:

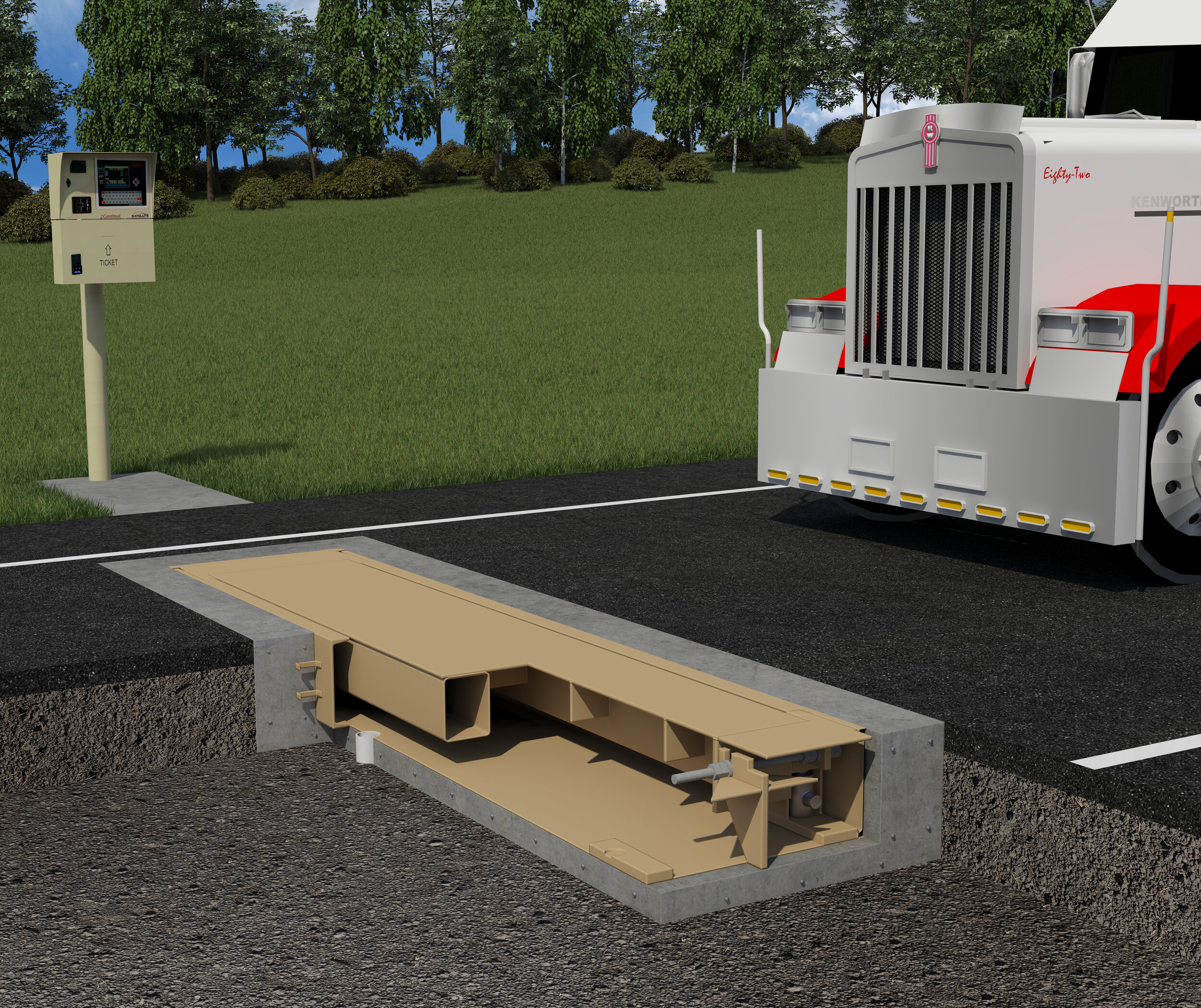

1. Setting The Scale:

Prior to setting the scale your foundation will be complete. To learn more about truck scale foundations check out this blog post. Setting the scale involves using a crane, loader, or other lifting equipment to offload the truck delivering the scale and placing the scale modules onto the foundation. Setting the scale can be a lengthy or short process depending on whether there is easy access to the foundation. For example, setting a scale on a foundation located in an open field is a quick & easy process; however, setting a scale inside the tunnel of a feed mill facility is much more difficult due to height restrictions. Your scale company will also be the ones to arrange the logistics of the truck and crane. Once the truck scale is set on the foundation, it’s time to begin anchoring.

2. Anchoring The Scale:

After the scale modules are set on the foundation they will require adjustments to ensure they are aligned properly. Large breaker bars and interconnect bolts will help ensure the modules are in the correct location. Once the scale is in the correct location it will be set onto the base plates and load cells. At this point, the scale technician will begin drilling anchor bolt holes in the foundation and then installing and tightening the anchor bolts. At the end of anchoring, the scale should be secured to the new foundation and centered + level with the approaches & end-walls. Also any checking or adjustment bolts will be installed and set to the correct tolerances.

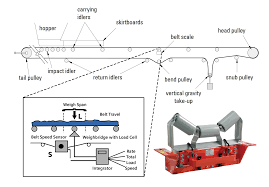

3. Wiring The Scale:

Depending on what brand and type scale you purchased, the wiring of the scale will be different for each. For most electronic truck scales, each loadcell’s cable requires running it to the junction box. Here, each loadcell cable will be landed on the internal board. The color coding for the wires on loadcells varies dramatically between different manufacturers, this is where a trained scale technician comes in. The final step is attaching the homerun cable to the junction box and running it to where your scale indicator will be located. At this point your truck scale is on the foundation, anchored, and wired to your scale indicator.

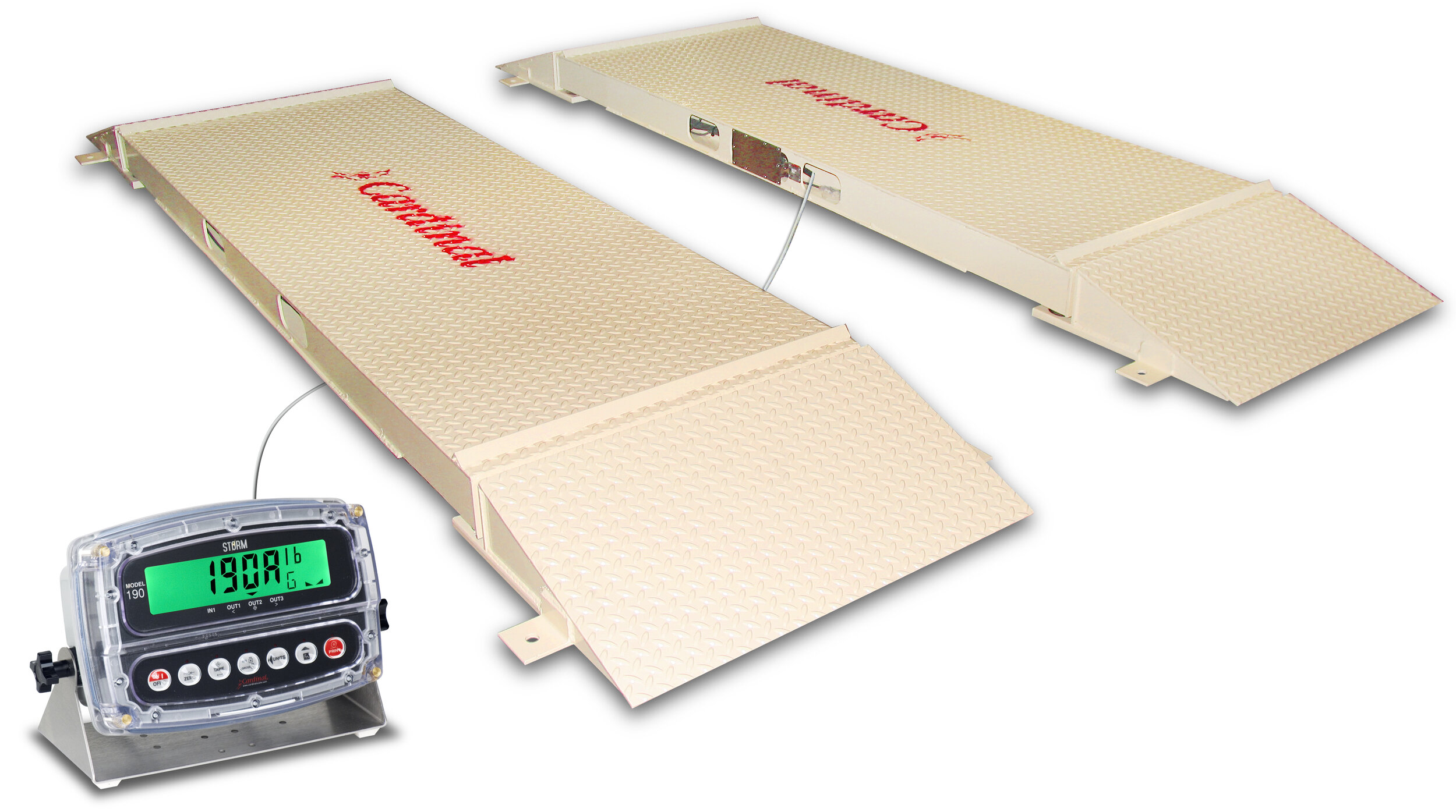

4. Setting Up Peripheral Devices:

In addition to the truck scale a number of other devices are normally connected to the scale indicator. Most states require legal-for-trade truck scales to have a remote display or scoreboard, to learn more about the requirements checkout this blog post. The scale technician will wire the indicator and program it to send the weight data to the remote display so the truck driver can see his weight while on the scale. Printers are another common peripheral device. Connecting the printer involves wiring the scale indicator to the printer and setting up a number of parameters to ensure the scale ticket prints correctly. Other peripheral devices can include outputs to HMI / PLCs, photo-eyes, etc.

5. Calibrating The Scale:

This step of the installation process involves calibrating your new truck scale to ensure it is weighing correctly. Your scale company will bring a heavy-capacity test truck on-site to use for this task. Known weights such as 20,000 lbs will be placed over each load cell and section during the calibration procedure. At the end of the calibration your truck scale will be weighing accurately. You will also receive a truck scale test report from your scale company outlining the results of the calibration.

6. Placed Into Service:

The final step that is required is if your truck scale is being used in a legal-for-trade operation then it will need to be placed into service with your state. This step is completed by your scale company and ensures you are legally allowed to start using your new truck scale.

As you can see, the process to install a truck scale has numerous steps and can range from simple to complex. To learn more about the cost of a truck scale, checkout this blog post.

Closing Words

At American Scale we strive to bring you informed and useful content on all things scale related. Be sure to check out our legal for trade truck scale system articles about truck scale foundation or how much do truck scales cost. We even have a guide to warranties. We also have articles on scale accessories, common problems to prolong your scales lifespan, weighing applications as well as what scale indicator works best with your junction box. To learn more about bench scales, it would be good to check out our other articles such as “Bench Scale Basics'' and “How Much Does A Bench Scale Cost?”. These articles will help with the basics of bench scale ownership.