A scale is a simple, yet very useful tool to have in your operation. When it comes to capturing weight measurements on larger objects (vehicles for example), you will want to start looking at different scale options. That is where axle scales come in. If your operation needs to capture large scale weight measurements but do not need the extent of a truck scale, then the axle scale may be a viable option. Axle scales come in a variety of forms, but all serve the same purpose: help you track how much weight a given product weighs to determine its exact dimensions. In this guide, we’ll explain everything you need to know about using an axle scale in your operation and why it’s worth investing in one for your company.

What is an Axle Scale?

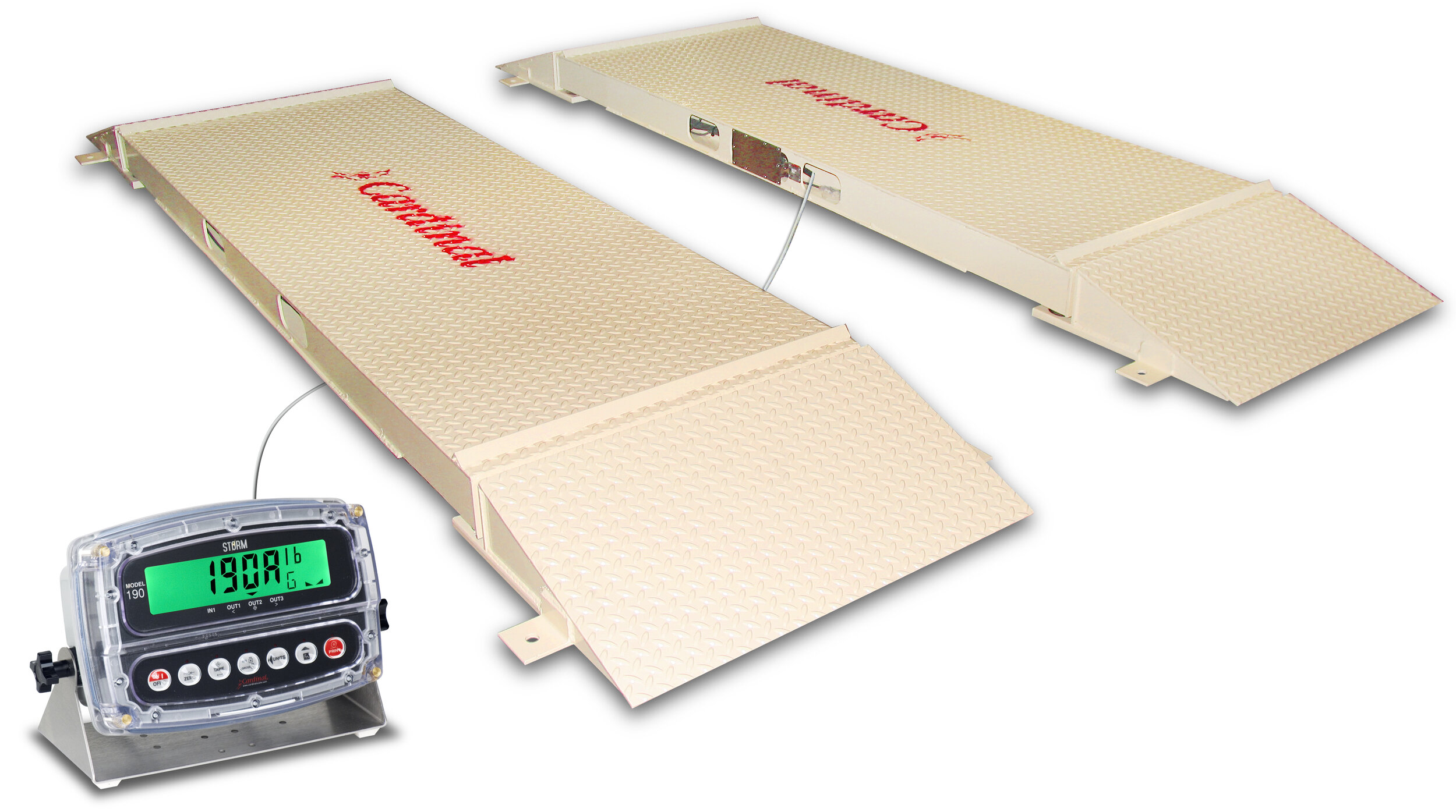

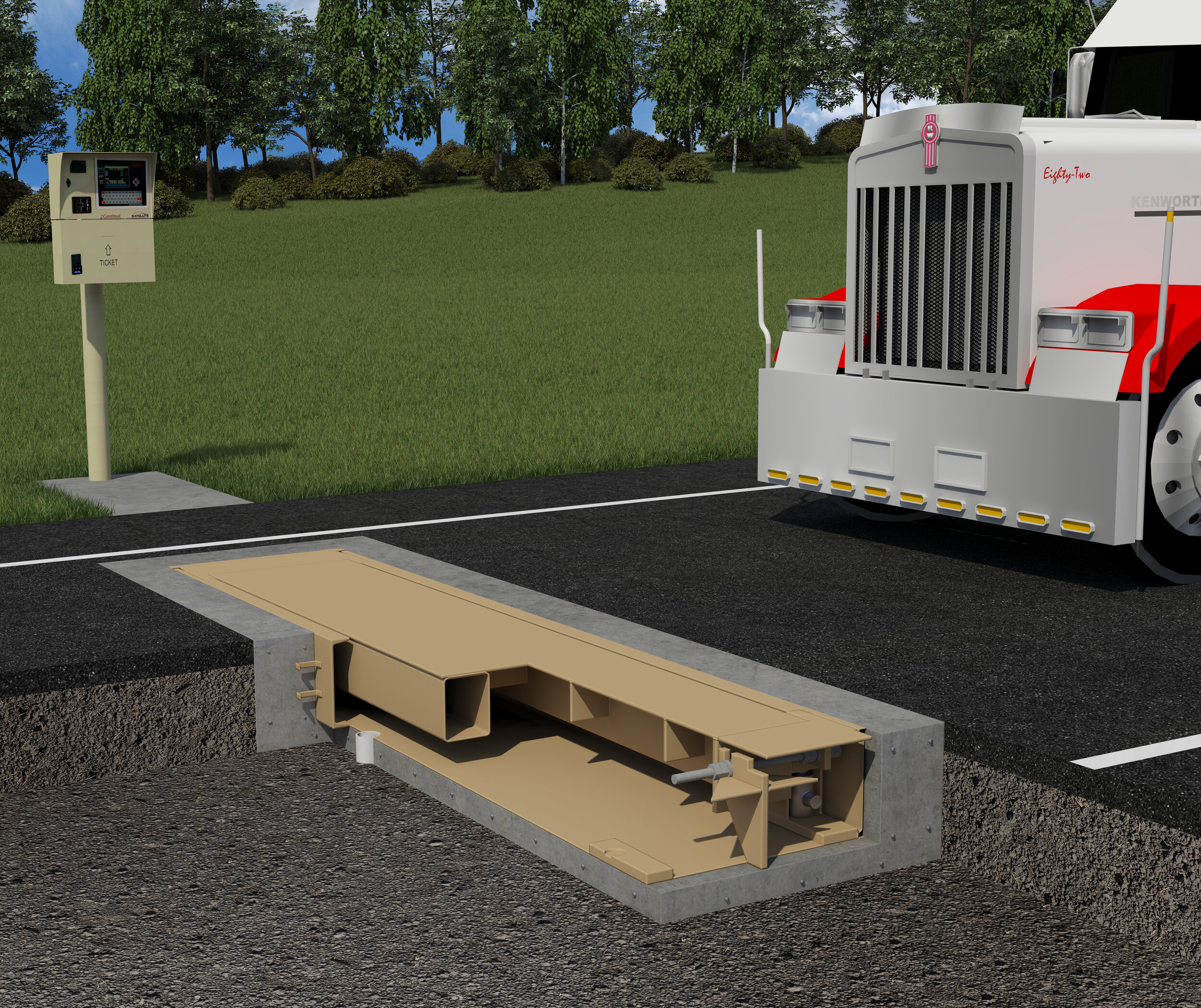

An axle scale is an instrument that measures the weight of axles so that you can accurately calculate their size, or load capacity. Unlike a full size truck scale, where you have to drive the entire load on to the scale to capture the weight. While different companies will use axle scales slightly differently, they all essentially work the same way. The setup may differ between places, but ultimately the process is the same. You have your scale, load cells, junction box and weight indicator. There may be accessories like a remote display or traffic light, but ultimately there is not much more to an axle scale.

Advantages of Using an Axle Scale

Like other scale types, there are certain advantages that an axle scale will have over a larger vehicle scale. Below is a list of some of the advantages that an axle scale offers:

Although axle scales cannot be used legal for trade they work well in many situations. They are great for gathering weight data to ensure trucks don’t leave a facility overloaded per DOT standards. They also take up significantly less space than a full size truck scale. This is a huge advantage for facilities with limited real estate to locate a scale. The footprint for an axle scale is only 33% of a full size truck scale. Axle scales are also more economical. This is because the scale itself is much smaller and requires less materials to construct. Similarly, any concrete foundation work is much less with an axle scale vs a full size truck scale. Finally, not all axle scales require installation requiring concrete foundations. Many can be installed on existing flat pavement and are therefore easier to install and move in the future if needed.

Should You Consider an axle scale?

Determining if an axle scale is the right choice for your operation depends greatly on what your needs are. Considering that it is not a legal for trade option, the scale would not be a viable option if you are looking for a legal for trade option.

Axle scales are able to find utility in applications ranging from shipping and construction to farming and logistics. The technology is constantly changing, and has forced scale manufacturers to design capable axle scales that can keep up with the demands of environment. Additionally, the creation of these types of scales has made it so that businesses can be in compliance with the rules put in place around load transport.

Reliability and ease of use are the main components of a good axle scale. The decision to invest in an axle scale is a good way to stay compliant with local and state regulations as well as keeping safety as a top priority for you and your site workers. An axle scale is a great investment if you need to save space, time and money.

Final Words

When manufacturing products, you have to worry about many factors. If you choose the wrong sizes for your products, you could end up with a quality issue or even a safety concern. Determining the exact dimensions of a product and knowing the weight it can handle is a good way to prevent problems. An axle scale can help you do this. We hope this article has helped you better understand how axle scales work and why it’s worth investing in one for your company.

At American Scale we strive to bring you informed and useful content on all things scale related. Be sure to check out our legal for trade truck scale system articles about truck scale foundation or how much do truck scales cost. We even have a guide to warranties. We also have articles on scale accessories, common problems to prolong your scales lifespan, weighing applications as well as what scale indicator works best with your junction box. To learn more about bench scales, it would be good to check out our other articles such as “Bench Scale Basics'' and “How Much Does A Bench Scale Cost?”. These articles will help with the basics of bench scale ownership.