Industrial scales play a vital role in a wide range of industries, from manufacturing and logistics to agriculture and pharmaceuticals. These robust weighing systems are designed to handle heavy loads and provide accurate measurements, making them essential tools for businesses seeking precision, efficiency, and compliance with industry standards. However, selecting the right industrial scale can be a daunting task, given the multitude of options available on the market. This article aims to guide you through the process of choosing the perfect industrial scale for your specific needs, taking into account various factors that should influence your decision-making.

Determine Your Weighing Requirements

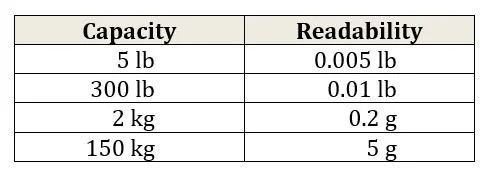

The first step in selecting an industrial scale is to define your weighing requirements. This means that you need to know what you will be weighing and the frequency that you will be weighing those items. Think about what the maximum weight you will measure throughout your operation. Consider the maximum weight capacity needed, as well as the minimum weight increments necessary for accurate measurements. Determine whether you need a scale for static weighing or dynamic weighing, or if you require additional features such as counting or check weighing capabilities. Depending on the type of operation you have will determine which features, capacities and scale size you will need. These features mentioned are important to helping you know what the best scale is for you. Understanding your specific weighing needs will help narrow down the options.

Consider Environmental Factors:

The operating environment of the industrial scale is crucial for its performance and longevity. Depending on your environment will greatly determine what type of scale you will need. Assess factors such as temperature variations, humidity, dust levels, and exposure to corrosive substances. The environment that your scale will be in will greatly affect the scale’s performance if it is house in an improper area. Depending on the conditions, you may need a scale with a higher IP (Ingress Protection) rating to ensure it can withstand harsh environments. Consider if the scale will be used indoors or outdoors, as this will impact the choice of materials and construction.

Evaluate Accuracy and Calibration:

Accurate measurements are vital in many industrial processes. Look for scales that adhere to recognized accuracy standards such as those set by the International Organization for Legal Metrology (OIML) or the National Institute of Standards and Technology (NIST). Consider whether you require legal-for-trade scales, especially if you are involved in commercial transactions by weight. Additionally, evaluate the calibration process of the scale and determine if it can be easily calibrated on-site or if it requires professional calibration.

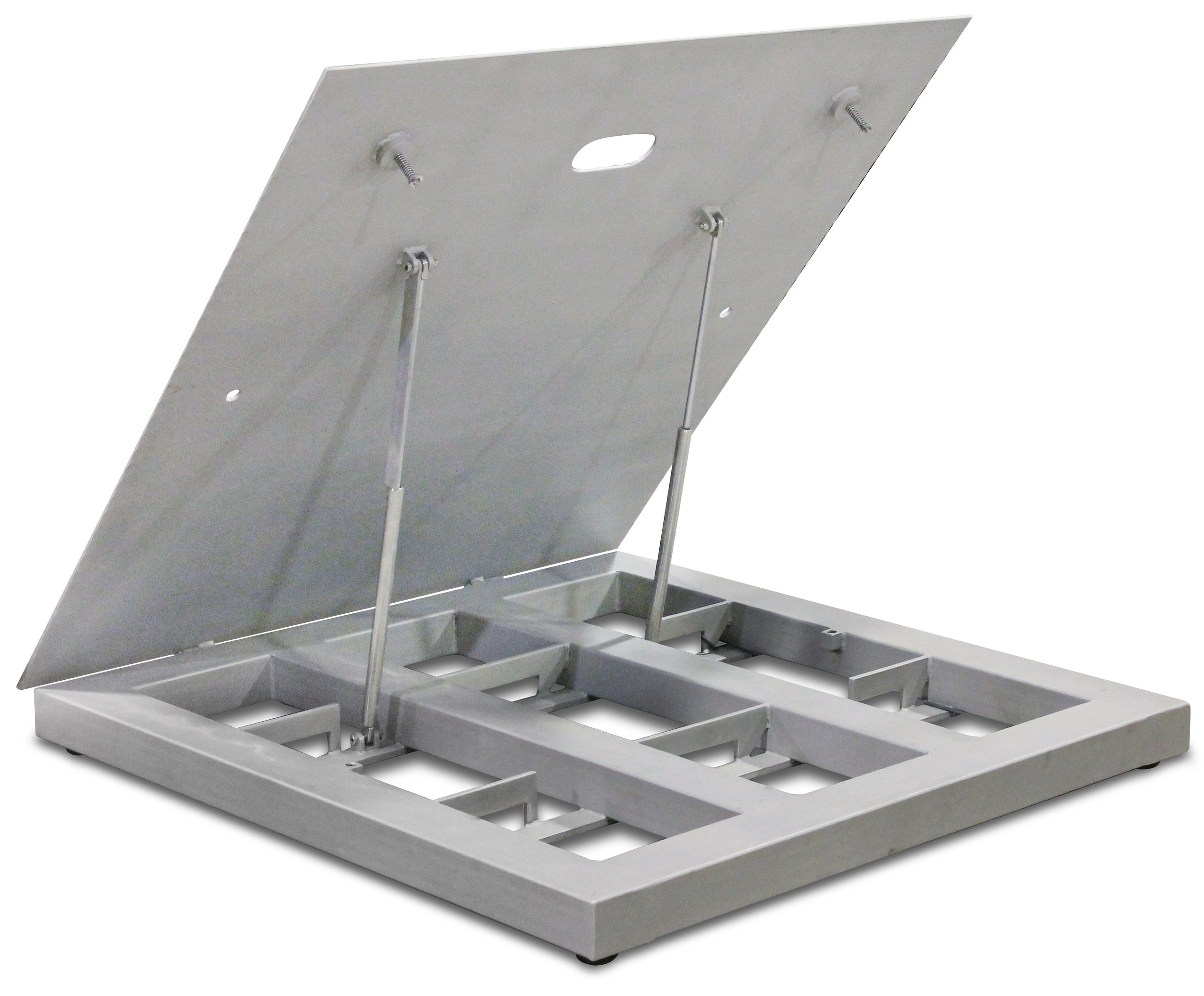

Inspect Scale Construction and Durability:

Industrial scales are subjected to heavy use, so their construction and durability are crucial factors to consider. Look for scales made from robust materials such as stainless steel or heavy-duty aluminum that can withstand the rigors of your industry. Consider the load cell technology used in the scale, as it directly affects accuracy and durability. Load cells can be strain gauge, electromagnetic force restoration, or capacitive, each with its own advantages and suitability for different applications.

Analyze Safety Features:

Safety is paramount in industrial environments. Look for scales with safety features such as overload protection, anti-slip platforms, and audible alarms. Consider if the scale requires additional safety certifications based on your industry's regulations, such as ATEX certification for hazardous environments.

Evaluate Connectivity and Data Management:

In today's digital era, connectivity and data management capabilities are increasingly important. Determine if you require a scale with built-in connectivity options such as Wi-Fi, Ethernet, or Bluetooth, allowing seamless integration with other systems or data transfer to a central database. Consider if you need a scale with advanced software for data analysis, reporting, and traceability.

Consider Maintenance and Support:

Industrial scales, like any other equipment, require regular maintenance and occasional repairs. Look for manufacturers or suppliers that provide comprehensive support services, including technical assistance, spare parts availability, and warranty coverage. Consider the reputation and reliability of the manufacturer, as well as the availability of authorized service centers in your area.

Compare Prices and Return on Investment (ROI):

Price is a significant consideration when choosing an industrial scale, but it should not be the sole determining factor. Compare prices from different suppliers while considering the features, durability, and support provided. Focus on the long-term return on investment (ROI) rather than just the upfront cost. A scale that offers enhanced accuracy, durability, and efficiency may prove more cost-effective in the long run, reducing downtime and potential losses.

You can reach out to one our representatives to get a free consultation or a quote on a specific scale system that you need. Configuring a scale can have multiple factors, but working with a scale company can make the journey a lot simpler. Be sure to contact us for a free consultation.

Conclusion:

Choosing the right industrial scale is a critical decision that can impact the efficiency, accuracy, and profitability of your business. By considering your weighing requirements, environmental factors, accuracy, construction, safety features, connectivity, maintenance, and ROI, you can make an informed choice. Take the time to research reputable suppliers, consult with industry experts, and thoroughly evaluate the options available. A well-chosen industrial scale will not only meet your current needs but also provide a solid foundation for future growth and success in your industry.