Weigh stations play a crucial role in ensuring road safety, preventing vehicle overloading, and maintaining infrastructure integrity. These stations are essential for monitoring and regulating the weight of commercial vehicles. However, traditional weigh stations have long been associated with challenges such as traffic congestion, inefficiency, and operational limitations. The emergence of remote kiosks has brought about a transformative shift in the way weigh stations operate. In this article, we will explore the numerous benefits that remote kiosks offer to weigh stations and how they are revolutionizing the industry.

Enhanced Efficiency

One of the primary advantages of remote kiosks is the significant improvement in the efficiency of weigh station operations. By implementing remote kiosks, authorities can streamline the process of weighing and monitoring vehicles. Rather than relying solely on manual inspections and physical interaction with drivers, remote kiosks leverage advanced technologies such as sensors, cameras, and automated weighing systems. This automation allows for faster processing times, reducing wait times for truck drivers and enabling a smoother flow of traffic through the weigh station.

Increased Accuracy

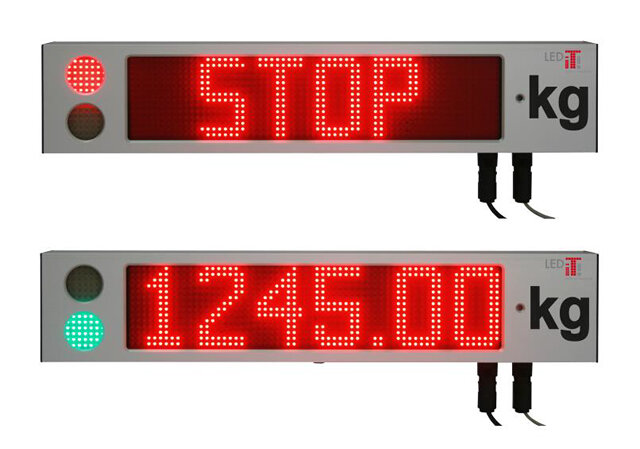

Traditional weigh stations rely heavily on manual data entry and recording. This process is prone to human error, leading to inconsistencies and inaccuracies in weight measurements. Remote kiosks, on the other hand, employ sophisticated weighing technologies that provide precise and reliable measurements. Automated systems integrated into remote kiosks ensure that the weight data is accurately recorded, minimizing discrepancies and enhancing the overall accuracy of the weighing process. This accuracy improves compliance with weight regulations and strengthens enforcement efforts.

Real-time Data Monitoring

Remote kiosks leverage connectivity and data transmission capabilities, allowing weigh station operators to access real-time data remotely. This feature provides invaluable benefits for monitoring and managing weigh station operations. Operators can monitor traffic patterns, vehicle weights, and other vital information from a centralized location. Real-time data monitoring enables proactive decision-making, such as identifying overweight vehicles before they reach the station, optimizing resource allocation, and facilitating targeted enforcement actions. Overall, remote kiosks empower authorities with comprehensive situational awareness and promote efficient traffic management.

Improved Safety

Weigh stations are not only responsible for enforcing weight regulations but also ensuring road safety. Overloaded vehicles pose significant risks, including compromised braking performance, increased tire wear, and potential damage to road infrastructure. Remote kiosks contribute to improving safety by reducing the time vehicles spend at the weigh station. This reduction in waiting times minimizes the likelihood of accidents caused by traffic congestion near weigh stations. Additionally, the automation of weighing processes reduces the need for manual intervention, decreasing the chances of human error and accidents during the weighing process itself.

Cost-effectiveness and Scalability

Implementing remote kiosks can offer substantial cost savings for weigh station operators. Traditional weigh stations often require significant investments in infrastructure, such as weigh bridges and manned booths. Remote kiosks, on the other hand, have a smaller physical footprint and require fewer personnel. The automated systems integrated into remote kiosks streamline operations, reducing labor costs and increasing productivity. Furthermore, remote kiosks are scalable, allowing for easy deployment and expansion as needed, making them a flexible and cost-effective solution for weigh station management.

Enhanced User Experience

Remote kiosks contribute to an improved user experience for truck drivers and other road users. By minimizing wait times and automating the weighing process, remote kiosks reduce the inconvenience and frustration associated with traditional weigh stations. Truck drivers can quickly and efficiently pass through the weigh station, reducing delays and ensuring timely deliveries. The user-friendly interfaces and intuitive operation of remote kiosks further enhance the overall experience, fostering positive interactions between authorities and the trucking industry.

Conclusion

The integration of remote kiosks has brought significant benefits to weigh stations, revolutionizing the way these critical facilities operate. The efficiency, accuracy, real-time data monitoring, improved safety, cost-effectiveness, scalability, and enhanced user experience offered by remote kiosks have transformed weigh station operations. As technology continues to advance, we can expect further innovations in remote kiosk systems, paving the way for a safer, more efficient, and interconnected road network. By embracing these advancements, authorities can unlock the full potential of remote kiosks and continue to optimize the vital role of weigh stations in the transportation industry.